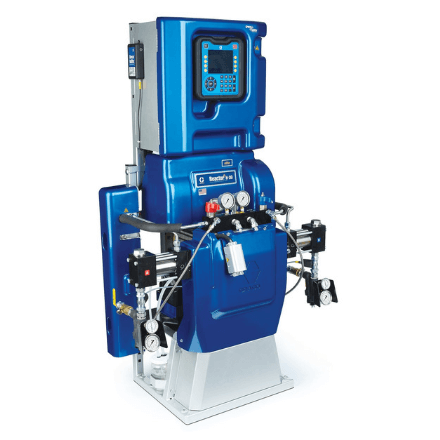

H-XP2, SEL, 15KW, HR2 | Graco’s hydraulic Reactor H-XP2 brings increased yield and high output spraying. Ideal for in-plant OEM’s or applicators that spray at high volumes.

GRACO REACTOR 2 H-XP2 | SEL | 15KW | HR2 | #17H062

$43,430.00

Description

Count on the Reactor 2 E-XP2 proportioner for advanced technology in applying fast-curing polyurea coatings. Because it’s a Reactor 2 series proportioner, it offers software and hardware enhancements for better spray performance, plus technologies that add to your bottom line.

The Reactor 2 E-XP2 is engineered to process and spray polyurea and other coatings that require high pressures. The hybrid heater and heated hose condition the materials to the right viscosity prior to mixing. Quick knockdown lower pump for easy maintenance, easy-to-use controls, and rugged design make the Reactor the preferred choice for coatings applications.

Reactor 2 E-XP2 gives you:

- Compact footprint – more room in your spray rig

- Ergonomic design – easier to service

- Advanced control modules

- Better spraying performance compared to traditional electric Reactor systems

- Troubleshooting made quick and easy with QR codes

Graco InSite™ gives you:

- Better control – manage your polyurea business wherever you are

- Better documentation – automatically collect job log data and spray parameters – lets you confirm the job was sprayed to specifications

- Better fleet and crew management

- Better cost containment and forecasting

- Graco InSite comes standard on all Elite models of Reactor 2

Features

- Advanced control technology

- Tracks, monitors and saves project data

- Data can be saved and downloaded onto a USB drive

- Stores up to 24 chemical recipes

- Drum level indicators

- Graco InSite Remote Reporting Technology

- Transmits real-time job activity you can view on your smart phone, tablet or computer

- Standard on Elite models

- Quick and easy troubleshooting thanks to QR code shortcuts

- Results in less downtime

- Easy to reach, conveniently-placed electronics

- Advanced control modules

- Handles power fluctuations

- Sacrificial surge protector

- Protects your electronics against excessive power spikes

- Smooth, consistent spray performance – similar to hydraulic systems

- Three-year warranty

- Covers user display module, control modules and electric motor

- One of the best in the industry

Materials

- Plural Component Protective Coatings

- Polyurea

- Polyurethane Coatings

Applications

- Roof Coatings

- Rust Proofing

- Ship Building & Marine

- Bridge Protective Coatings

- Railcar Manufacturing and Repair

- Pipe and Tank Coating

- Structural Steel Coating

- Wastewater Treatment

- Secondary Containment Spill Prevention

- Corrosion Control

- Offshore Rigs

- Spray on Bedliners

- Waterproofing

Industries

- Spray Booths

- Flooring and Maintenance

- Marine and Shipyard Maintenance

Product Data & Resources

All Graco Reactor 2 E-XP2 documentation, manuals and resources available HERE.

Below the most important manuals provided by the manufacturer:

Graco Reactor 2 E-XP2 | Operation Manual >

Graco Reactor 2 E-XP2 | Repair & Parts >

All GRACO Fusion Air Purge documentation, manuals and resources available HERE.

Below the most important manuals provided by the manufacturer:

GRACO Fusion Air Purge | Instructions and Parts >

GRACO Fusion Air Purge | Hoses – Guns – Accessories >

Additional information

| Weight | 695 lbs |

|---|---|

| Maximum Fluid Working Pressure | 3500 psi |

| Maximum Fluid Temperature | 190°F |

| Maximum Flow Rate | 2 gpm |

| Maximum Heated Hose Length | 310 ft |

| Output per Cycle, ISO and RES | 0.0203 gal |

| Operating Ambient Temperature Range | 20° to 120°F |

| Line Voltage Requirement | Nominal 200–240 VAC, 1 Phase, 50/60 Hz – 195–265 VAC |

| Heater Power | At 230 VAC rated voltage |

| Sound Power | ISO 9614–2 |

| Sound Pressure | 3.1ft (1m) From Equipment |

| Fluid Inlets | Component A ISO) and Component B (RES) |

| Fluid Outlets | Component A (ISO) Component B (RES) |

| Fluid Circulation Ports | Size: 1/4 NPSM(m) |

| Weight | 345 lb |

| Width | 26.3 in. |

| Height | 63 in. |

| Depth | 15 in. |

| Wetted Parts | Aluminum, stainless steel, zinc plated carbon steel, brass, carbide, chrome, chemically resistant o-rings, PTFE, ultra-high molecular weight polyethylene |