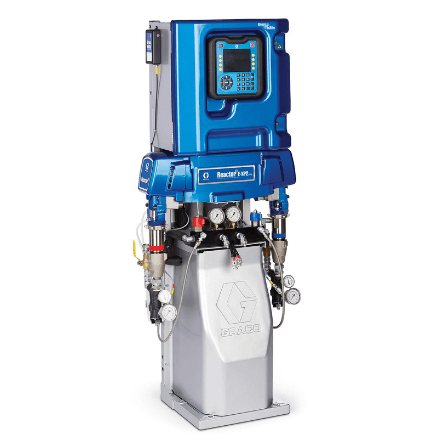

XP1, 10.2KW, 230V, 1PH | For polyurea coatings – applies up to 2 gal (7.6 liters) per minute.

GRACO REACTOR / E-XP1 / 10.2KW / 1PH / # 259024

$26,840.00

Description

Graco Reactor E-XP1 proportioner is engineered to process and spray polyurea and other coatings that require high pressures. The hybrid heater and heated hose condition the materials to the right viscosity prior to mixing. Quick knockdown lower pump for easy maintenance, easy-to-use controls, and rugged, portable design make the Reactor the preferred choice for coatings applications.

Graco also offers an electric proportioner in its new Reactor 2 series, the Reactor 2 E-XP2. Count on Graco Reactor E-Series proportioners for power, performance and productivity on fast-curing polyurea coatings. And get the job done faster and more reliably than ever before.

Features

All Graco Reactor E-Series Proportioners provide:

- Powerful hybrid heater provides up to 15,300 watts of heat to pre-heat material quickly

- Digital heat and pressure controls

- Easy to use

- Quick knockdown lower pumps for easy maintenance

- Rugged and portable

- Circulation valves with long-lasting seals

- Hose heat transformer that doesn’t require tap settings

Applications

- Ship Building & Marine

- Pipe and Tank Coating

- Wastewater Treatment

- Secondary Containment Spill Prevention

- Spray on Bedliners

- Waterproofing

Industries

- Commercial Painting & Texture Contractors

- Marine

- Railroads

Product Data & Resources

All Graco Reactor E-XP1 documentation, manuals and resources available HERE.

Below the most important manuals provided by the manufacturer:

Graco Reactor E-XP1 | Operation Manual >

Graco Reactor E-XP1 | Repair & Parts >

Graco Reactor E-XP1 | Electrical Diagrams >

Important

Amperage Requirement

See Table 1, page 20 in Graco Reactor E-XP1 | Operation Manual

Additional information

| Weight | 432 lbs |

|---|---|

| Dimensions | 43.2 × 33.6 × 57.6 in |

| Maximum Fluid Working Pressure | 2500 psi |

| Maximum Fluid Temperature | 190°F |

| Maximum Output | 1 gpm |

| Output per Cycle (A and B) | 0.0104 gal |

| Heater Power | 10200 Watts |

| Sound Power | ISO 9614–2 |

| Sound Pressure | 3.1ft (1m) From Equipment |

| Fluid Inlets | 3/4 npt(f), with 3/4 npsm(f) union |

| Fluid Outlets | Component A (ISO): Component B (RES): |

| Fluid Circulation Ports | 1/4 npsm(m), with plastic tubing; 250 psi (1.75 MPa, 17.5 bar) maximum |

| Weight | 342 lb |

| Wetted Parts | Aluminum, stainless steel, zinc plated, carbon steel, brass, carbide, chrome, chemically resistant o-rings, PTFE, ultra-high molecular weight polyethylene |

| Voltage Tolerance Range (50/60 Hz) | 200–240 V ac Nominal, 1 Phase, 195–264 V ac, 50/60 Hz |